Welcome to a new era in calf rearing with Creva International's innovative solutions that set the standard for excellence. Our curated selection of calf rearing solutions, featuring cutting-edge technologies from industry leaders like Urban calf feeders, Agri-Plastics calf housing, and OK Plast, redefines the landscape of nurturing young livestock. From precision-engineered feeders ensuring optimal nutrition to durable housing solutions and accessories, our comprehensive approach aims to elevate the well-being and growth of your calves. Complementing these advancements, our range of calf jackets adds an extra layer of protection, ensuring your young livestock thrives in comfort. Discover the pinnacle of calf rearing efficiency and welfare through Creva International's expertly curated solutions.

About the Urban Alma Pro

Calves benefit from being fed small amounts of milk multiple times a day for their development. The Urban Alma Pro transforms common day-to-day challenges into one convenient work step. Your calves are fed compassionately and individually around the clock, the milk concentration and temperature remain constant, and you and your team have noticeably less work. The Alma Pro is a complete solution that enables you to respond to the individual needs of each calf at any time. At the same time, you are able to organise your work processes more efficiently.

Benefits include:

- Species-appropriate feeding all around the clock

- Metabolic programming as a result of intensive feeding

- Consistent milk concentration

- Constant milk temperature

- Health monitoring

- Improvement of (feed) hygiene

- Improved growth rate

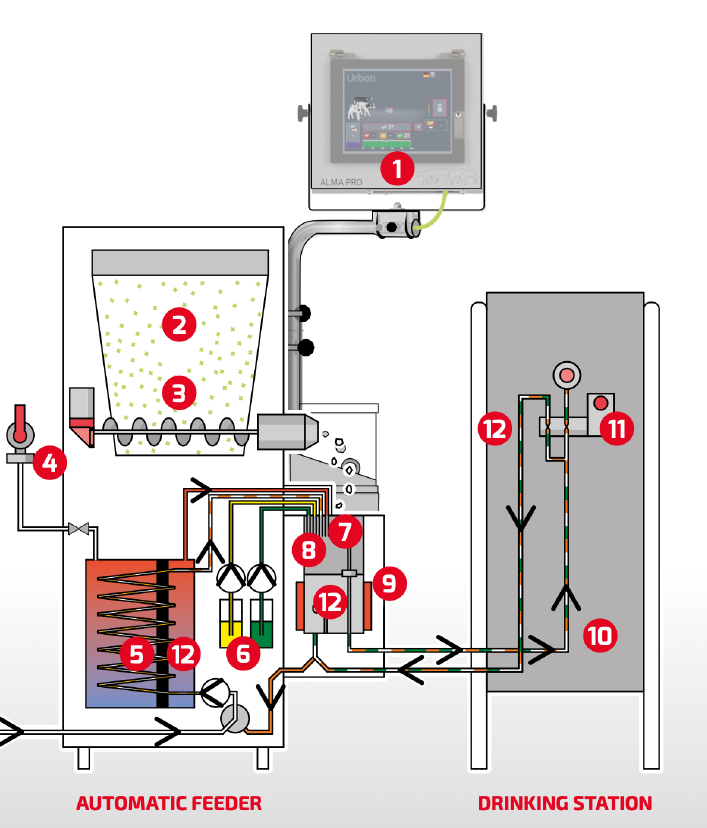

To make your work as easy as possible, the Urban technology is based on a simple structure and uncomplicated operation.

- Control panel with touchscreen and a clearly arranged user interface

- Storage container for milk powder with a capacity of 35 kg (can be increased to 55kg)

- The powder spiral ensures a consistently precise dosing of the milk powder

- Water connection

- Boiler / heater exchanger

- Cleaning agents (acidic and alkaline) for fully automatic cleaning

- Milk removal tap for easy tapping of milk

- Float in the mixing bowl which measures the dispensed amount of milk. This means that even small portions can be allocated to the calves with millilitre precision.

- Heated mixing bowl.

- Ring line - transports the milk to the teat. Periodic, temperature-regulated circulation between teat and mixing bowl ensures that the calves can always access warm milk and that the lines do not freeze if temperatures fall below zero.

- Station valve

- Temperature sensors - ensure that the milk is kept at a consistent temperature.

Operation and data retrieval via the integrated touch screen are extremely simple. The intuitive user interface allows for individual feeding and the comfortable creation of feeding curves.

- Herd overview - animal monitoring around the clock

- Health management - all data relevant to the health is stored and automatically analysed. Animals which behave conspicuously are marked orange or red which helps identify potential health issues and allow early intervention.

- 7 days food overview - in addition to the daily amount, the display shows the actual consumption for the past 6 days.

- Feeding curve - feeding curves can be easily adapted the special need of the calves. Multiple feed curves can be created with different amounts and concentrations.

- Mobile control (optional) - by pairing the device with the Urban wi-fi router, you can use all functions of the Urban Alma Pro with a smart device or PC.

- Container - the feeder is made from high-quality stainless steel and the compact design helps in saving space. The robust lateral edge and the low filling height (1.09m) makes it easy to fill.

- Animal identification - the animal is identified by transponder on the collar or electronic ear tag.

- Electronic station units - shows the amount of milk left to consume for the calf and monitors the milk temperature directly at the station.

- Cleaning programme - the integrated cleaning programme cleans all milk-distributing parts including the teat, alternating with tow different cleaning agents (alkaline and acidic). The cleaning process is fully automatic, thorough and reliable.

- Milk tap - milk can be taken from the machine at any time for feeding calves which are separated from the feeder.

The large range of optional equipment allows you to adapt the automatic feeder to your individual needs.

- Powder supply expansion - if the Alma Pro is used for large groups, the volume of the powder container can be increased to 55kg.

- Signal lamp - red, yellow, green - makes the status of the feeder clearly visible from a distance.

- Liquid additive doser - liquid additives such as vitamins or electrolytes are directly injected into the milk line. Delivery of the additives can be adjusted individually.

- Additional pre-heater with FitPlus - a second heater can be installed at request for higher performance. It significantly increases the heating capacity of the feeder and thus makes it possible to feed calves faster without breaks. The concept also includes a novel type of 2-phase cleaning: two different detergents can be used in a single cleaning sequence.

- Powder additive dosing unit - enables the automatic dispensing of powder additives such as vitamins or electrolytes - individually or to the whole group.

Drinking Stations:

- Standard Station - individual animal identification, safety bracket and quality teat - the feeding station with standard equipment already scores with numerous features.

- Hygenic Station UV-C - the HygieneSets UV-C quickly disinfects the teat chemical free and energy saving.

- Double Station - without bounce bar for larger space requirement and for simplified training of calves. It can also combined with the HygieneSet UV-C

Our goal is to create functional, operation-specific solutions Our automatic feeder is suitable for small(est) and large groups and can be individually adapted according

to the purpose.

The installation of the Alma Pro depends on the conditions of the barn, the type of housing and the number of animals. While one feeder with two drinking stations may be sufficient for smaller farms, larger farms may need several feeders and feeding stations. This is the only way to ensure that each animal receives enough milk. We support you in planning the optimal technical set-up. It is possible to connect up to four drinking stations per automatic feeder. In addition, the number of automatic feeders per terminal can be increased to up to four.

Examples:

- Up to 35 calves: one feeder plus one station

- Up to 70 calves: one feeder plus two feeding stations

- Up to 100 calves: one feeder plus three feeding stations

- Up to 140 calves: one feeder plus four feeding stations

- Recommended FitPlus if 3 - 4 feeding stations

Other Recommendations:

- Teagasc recommendations for a shed suitable for an automatic calf feeder to allow 2.0m2 - 2.3m3 per calf

- Penning and gates set up should prevent calves from accessing feed pipes, antennae lead and other machine components.

- The machine needs to be positioned at the same level as the feed stations.

- Water requirements: 1⁄2 inch lever valve wall tap fitted so the feeder can be connected. Pressure must be constant - there needs to be a minimum of two bar pressure with a maximum of four bar. Recommend to install header tank and pressurised pump. This will help ensure the machine works at its optimum and prevent fluctuations

- Electricity requirements: Alma Pro Feeder needs a single x 16-amp single phase waterproof plug socket. Alma FitPlus Feeder needs a single x 32-amp single phase waterproof plug socket. Do not use extension leads. The machine will need to be earthed by a qualified electrician. For the pressurised pump a second 16-amp single phase waterproof socket will be required. A double socket is often advisable in case of routers or other being added in at a later date.

Farmer Phil's New Calf Feeder

Meet Farmer Phil, a proud advocate of innovation in farming! In the video below of his calf feeding set-up on his Co Longford farm, he unveils the latest addition to his calf care routine – the brand-new Urban Alma Pro feeder. In this insightful video, Farmer Phil takes us through the installation process and shares why he chose the Urban Alma Pro feeder for his farm. Discover the incredible features that make calf care a breeze!

Ready to change up your calf rearing practices?

Connect with us on WhatsApp for details of who your local distributor is and to unlock valuable insights into best practice calf rearing and feeding solutions. Whether you're seeking expert advice or eager to explore our range of innovative products from Urban Calf Feeders, Agri-Plastics, and OK Plast, our team is here to guide you. Don't miss out on optimising your calf care – send us a message now.

Free Download - Urban Installation Guide

Our free Urban download 'Preparing for the Installation of Your New Urban Feeder' provides farmers with a full run through of all the elements needed to ensure you have the smoothest and fastest Urban feeder installation. From the barn design to water and electricity to cleaning and maintenance, we have all bases covered.

Click on pdf icon to download.